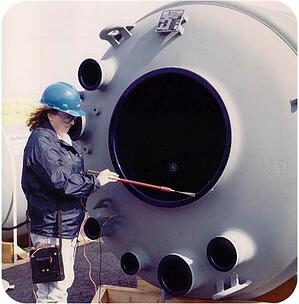

Spark testing of rubber lined vessel the rubber lining of the vessel is completed on the 12th december 2014 a full spark test is carried out pre vulcanisation.

Spark test procedure for rubber lining.

After installation and before cure the lining is to be spark tested at 15 000 volts 15kv and visually inspected for trapped air loose edges and damage to the rubber linings.

13 2 3.

The spark tester is to be calibrated using a test calibration block the same power source probe and cable length to assure the setting on the probe is unchanged.

This procedure is detailed below.

During testing the entire glass lined surface is examined and any chips cracks pinholes and other defects are documented and marked for repair.

5 way distributor rubber lining spark test.

Vessel is vulcanised on the same day once this process is completed the vessel then undergoes a final inspection as seen in photo this once gain includes a full spark test.

Technique visual inspection equipment maintenance and rubber lining application experience are all essential in reducing errors misinterpreting results and completing the spark test with meaningful result.

Test equipment 1 1 high frequency ac spark testers are.

Technique visual inspection equipment maintenance and rubber lining application experience are all essential in reducing errors misinterpreting results and completing the spark test with meaningful results.

Spark testing is not an absolute test meaning that it is not 100 fail safe.

To discuss your spark testing hardness.

It is important that the electrode be kept moving without stopping too.

How to identify metals with basic shop tools and the spark test tig time duration.

The proper way to spark test is to calibrate the voltage to a known leak.

The lining shall be free of blisters porosity and tears.

Spark testing is not an absolute test meaning that it is not 100 fail safe.

Rubber lining application manual revision date.

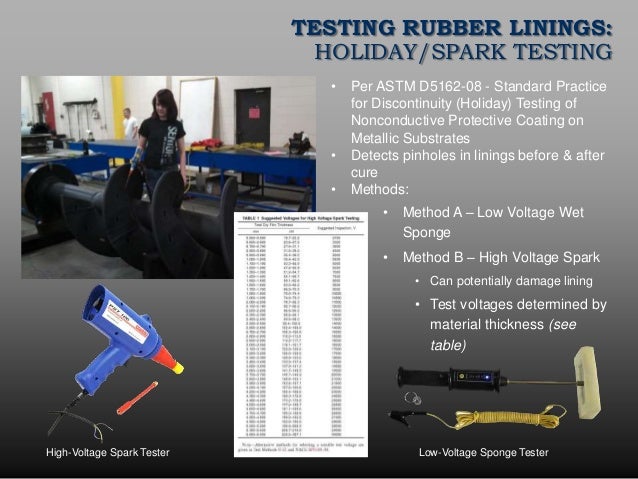

One of the biggest mistakes is done when specifying the voltage.

Spark testing method is a test method of checking the quality of the rubber lining or rubber coating on the internal as well as external surface of the react.

There are two apparatuses available for spark testing dc and ac spark testers.

September 1 2009 section 13.

The purpose of spark testing is to determine if there.

Rubber is to be supported so as not to be stretched during application.

Spark testing rubber lining spark testing can cause more damage and leaks than it may discover if done improperly.